You are here: Home > Products > Chemical > Microwave Digestion/Extraction Workstation > MASTER-15/18/40/70Products

MASTER-15/18/40/70

Ultra High Throughput Closed Microwave Digestion/Extraction Workstation

Ultra High Throughput Closed Microwave Digestion/Extraction Workstation

The 40-vessel high throughput microwave digestion/extraction workstation developed by us in 2010 obtained pleasant feedbacks from the market. Based on this, we further develop microwave sample preparation equipment to an unprecedented level in 2012. The new MASTER 70-vessel ultra high throughput closed microwave digestion/extraction workstation, surpassing all similar products on the market, shall be an achievement of we after profound accumulation on the research of microwave chemistry instrument for 20 years, and its core technologies, including the material and processing technology of outer vessel of digester, design of high throughput digestion rotor, unique pressure measuring technology by piezoelectric crystals and the patent technology of continuous rotation of digestion rotor in one direction inside the chamber, are even better than those similar goods on the market and all shows our innovations andbreakthroughs for the industry.

With the popularity of analytical instruments, e,g, Mass Spectrometer, there are increasing demands of rapid and efficient microwave sample preparation instrument with high productivity. However, the present high throughput microwave digestion products on the market are those which may bear low pressure, be easy to be leaked, have flexible covers, may not be heated evenly and operated easily. Our new MASTER closed microwave digestion system is such an high throughput microwave sample preparation instrument which is developed by aiming at coping all the abovementioned problems, and the followings may show its unique characteristics of the innovative technologies:

1. The high throughput vessel, since being connected by the high tensile alloy draw bar, may withstand great pressure (≥10000Kg). Each digestion vessel may receive great supports from the vessel frame on its top and bottom and it may not be deformed or leaked under the pressure of ≤4MPa and temperature of ≤250℃. (However, those similar products made by other venders generally may bear the temperature of 210℃ maximally.)

2.The high throughput vessel frame may homogenize the microwave field inside the chamber with the turning and stirring of frame vessel; therefore, 40-70 high throughput vessels may be heated evenly in the microwave field.

3.Instead of explosion-proof membrane and other consumables, it applies device of pressure relief blowout disc, and it may ensure the digestion vessel be closed completely under normal working conditions (with pressure of 4MPa and temperature of ≤250℃). The blowout disc will blow out automatically when the pressure is large enough and may constitute a danger to the safety by means of raising the cover to release the pressure through vertical quantitative explosion, therefore, the safety of the operation may be well guaranteed. Under normal operation, the pressure relief blowout disc will not blow out and requires no replacement.(However, those similar products on the market may start to release the pressure through the deformed cover in the case of over 200℃, and since the cover is not made of metal, it may not recover after deformation; consequently, it may be not flexible anymore and be useless as it loses its sealing function after several times of recovering. This is why the samples inside the digestion vessel are reduced or dried and it has low recovery rate.)

4. The temperature-pressure measuring and control device and digestion vessel may turn with the rotary table (vessel carrousel) in the same direction, The patented technology of junction box,instead of rotating back and forth in 360 degrees, may make the rotary table (vessel carrousel) turning in one direction without a break, so the microwave may heat samples more evenly; besides, the cable for such device is short, therefore it may be free from twisting in the running and may be disassembled easily; and motor of rotary table has small load but long service life.

5.The various convenient operation tools may lessen the working burden of operators and increase the preparation efficiency of samples. Let’s take the flexible trolley as an example. Such device may help the experiment personnel to place the high throughput rotary table with fully loaded samples (weighing 15-20kg) in the chamber and take it out easily. In this manner, the operator may not be required to contact the high-temperature and high-pressure digestion vessel directly and will not be injured by acid mist, perfectly ensuring the safety of the operation. The electric tool with fixed moment to close and open the digestion vessel may make the operation of high throughput digestion vessel rapid, simple and fulfilled.

General technical features:

1.Outer explosion-proof vessel made of composite fibers, better than those similar products on the market .The composite fibers have been widely used in aircraft skin of Boeing 787 and Airbus 380. It, light, thin and flexible and having better hardness (better than metal) and good rigidity, is an ideal substitute of metal. Moreover, its pressure resistance and corrosion resistance performances are much better than PEEK (Poly-Ether-Ether-Ketone) outer vessel. In addition, other vender’s products on the market usually have its two end faces open, so it may be easily penetrated and corroded by acid mist. Then, the inner vessel may start to leak gas due to the deformed top and bottom with poor strength. As for this, Chincan, by applying PFA complete packing and painted PFA processes, improves the corrosion-proof capacity by packing the composite fibers totally. Moreover, it may withstand pressure of 10000psi and temperature of 500-600℃, therefore, it may be called a type of high tensile invincible composite material.

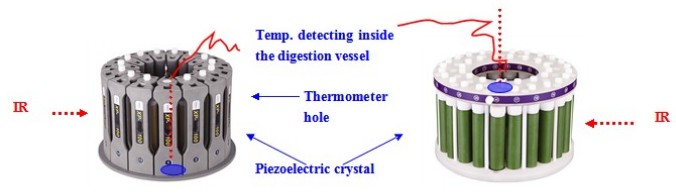

2. Advanced and reliable pressure measuring technology by piezoelectric crystal At present, the air-pipe is generally applied to transmit, measure and control the pressure inside the vessel for most venders. The air-pipe has apparent demerit that is too long, usually 400-600mm in length.

Hence, it may be twisted and broken easily. Besides, it has high sealing requirement, the samples in master vessel may be polluted easily, and to prevent breaking the air pipe, it may not withstand high pressure. In addition, the digestion rotary table shall rotate back and forth in 360 degrees to avoid the air-pipe being twisted.Therefore, as for this, after years of research and development, we acquires the pressure measuring technology by piezoelectric crystal, reliable and durable. Such technology may measure and control the pressure under 12MPa. The measuring and control cable is quite short, only 120-140mm, therefore, there will be no twisting, sealing joint or leakage. Such technology allows easy operation and its greats merit is the absolute isolation of measuring and controlling component and sample, thus giving no chance to cross contamination.

Piezoelectric crystal is installed on the bottom or top of the vessel frame like an electronic balance, and the parameter of pressure will be delivered via electrical signal.

Integrating the technology of synchronous rotation of temperature-pressure device and digestion vessel with the rotary table in one direction and the patented technology of junction box, the rotary plate may rotate towards one directly constantly. The pressure control system, is the standard configuration of our product, not optional.

3. The temperature inside the digestion vessel may be monitored and controlled entirely by the combination of precise measure of temperature inside master vessel and IR temperature scanning The precise measurement and control of temperature inside the master vessel (Pt or optical fiber) combines with the IR temperature scanning, and the computer may identify the master vessel automatically and give the real-time comparison of temperature with standard vessel, more precise and reliable than only IR temperature measuring.

4. High throughput rotor with optional strong magnetic stirring function specially for extraction or synthesis Ultra high pressure and high temperature 18-vessel digestion vessel and rotor may work under 6MPa and 260℃, quite suitable for digestion of insoluble samples or closed microwave synthesis under extreme conditions. The strong magnetic stirring function is available and optional.

5. 70-vessel ultra high throughput closed microwave digestion vessel and rotor, breakthrough products for the industry To adapt to the rapid development of advanced analytical instrument, the requirement for limit of detection, volume of sample, acid amount and blank interference are decreased, but the amount of samples to be detected are increased. Therefore, it, small volume, good pressure-bearing capacity and excellent batch processing performance, has become the trend for the development of microwave digestion technology. we creatively develop the unique 70-vessel ultra high throughput microwave digestion vessel and rotor based on the previous designs and technologies of high throughput products. Such product is well received by the users in geological industry, food industry, sanitary inspection industry and environment industry. The 70-vesssel digestion vessel has 3 volume specifications, 15ml, 25ml and 45ml, and it may be customized according to the specific requirement of the user.

6.One for All

This MASTER series product, may suit different digestion vessel sets and satisfy the requirements of users in different industries and application areas. You may use vessels and rotors in different quantity, temperature/pressure bearing capacities and volume flexibly.

7. Real high efficiency Inverter microwave control technology realizes continuous non-pulse microwave heating. Nearly all the similar products apply transformer microwave power supply, and no products use the Inverter technology. Therefore, the output power of double magnetrons is smaller than 2000W. Our MASTER Series products adopt advanced high efficiency Inverter microwave power supply, and their maximum output power of double magnetrons may be 2200W, allowing the synchronous heating of 70 vessels. During the heating, the control output power may be fed back automatically with the reaction temperature and pressure, and continuous non-pulse microwave heating may ensure the reaction of safety and high efficiency..

8. It may enter cooling procedure of digestion vessel automatically and cool it down by high speed air with double air velocity control system; therefore, it may complete the cooling in 15-20 minutes, requiring no cooling by water

9. The complete digestion database after safety verification, fulfilling the international standards of US-EPA and ASTM, is provided with over 1000 methods, and has been referred to in several international standards, industrial standards and pharmacopoeia.

10. We has 20 years of experience on the research and development of microwave chemistry instrument, and its staff all have rich and proven experiences as half of them have been working in the company for over 10 years. It has ISO 9001:2008 certificate in design of microwave products. Moreover, its products have gotten EU CE safety certificate, and its corporate standards in electromagnetic compatibility, microwave leakage and electric protection go beyond national and international standards. In addition, the company has fully participated in the preparation, issuance and implementation of national standard for Microwave Digestion Device (GB/T 26814-2011)

11. Other technologies and processes:

a. The industrial stainless steel chamber is painted with PFA both inside and outside and conducted with industrial preservative treatment to resist strong acid and alkali,and it may with stand high temperature of 350ºC

b. The cushioning design of 6-storey steel structure auto-floating explosion-proof door may release the high pressure inside the chamber; and it has electrical and mechanical control door locks and is equipped with self-checking system for locking of door.

c. The high-definition LED display may show the reaction parameters and change of curves in real time on different interfaces, convenient for the modification of the setting of reaction parameters and the saving of digestion solutions as per their types.